Equipment and Innovations

Pick All Truck

The Pick All Truck is a fully integrated, joystick-controlled debris collection system, engineered to streamline and automate pickup functions directly from inside the truck cab. Now in its third-generation design, the Pick All Truck features dual steering wheels and dual joysticks, enabling a single operator to control every mechanical movement without leaving the vehicle.

From the control interface, a series of pre-programmed and custom operations handle the entire debris collection process. With the push of a button, the pickup head is dispatched to a designated point. Joystick movement completes the retrieval, and the debris is transferred into the receiver hopper and into

The process repeats on the opposite side without requiring manual repositioning. Operators can raise the pickup head, activate trail mode, shut the tailgate, run the compactor, or initiate a complete dump cycle. Ultimately, the system automatically resets the truck body and prepares it for the next round..

This technology isn’t bound to one truck model or brand. It can be installed on a wide range of truck types, making it a flexible solution for municipalities, industrial facilities, and highway maintenance teams looking to increase safety and efficiency.

The Pick All Truck system is patented and developed by NuTrend Enterprises.

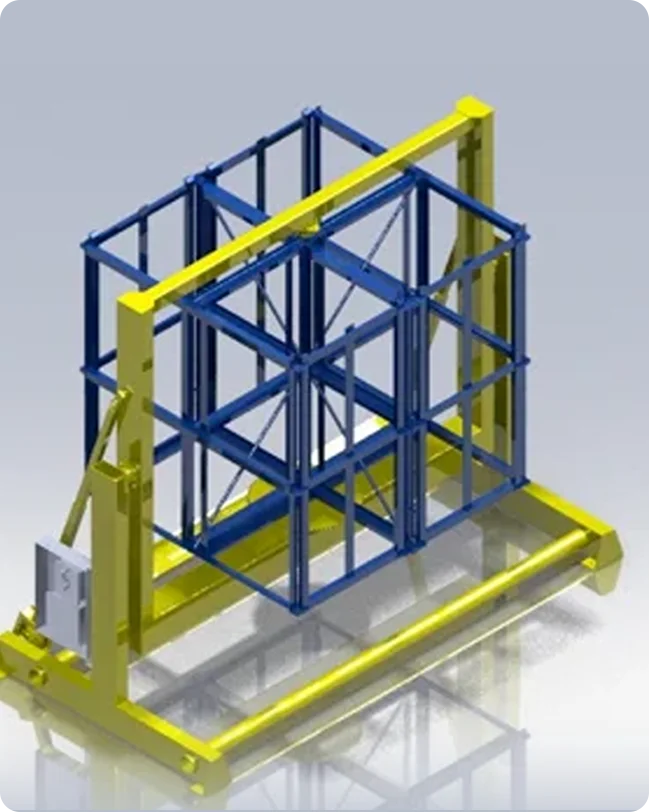

Riddler (VLM)

The Riddler (VLM) is a cornerstone of modern sparkling wine production. Originally developed in partnership with Domaine Chandon, this machine was built to match, and eventually exceed, the precision and consistency of traditional hand riddling..

Capable of handling up to 4,600 bottles in a 10-day cycle, the Riddler automates one of the most delicate processes in méthode champenoise: the gradual turning and tilting of bottles to consolidate sediment. With this machine, producers can achieve a high standard of quality while lowering the labor costs and inconsistencies associated with manual riddling..

The machine is built for durability. Its frame is constructed using steel channel, angle, and rectangular tubing. Bearings support all moving components. The two-motor drive system is powered by gearboxes rated at 1.5 hp for both tilt and rotation movements. An Allen Bradley programmable computer allows full customization of the riddling schedule to fit the producer’s process and preference..

The standard Riddler (VLM) has a footprint of roughly 16 feet wide, 15 feet tall, and 14 feet deep. Each machine is primed and painted for protection…

Units are priced between $70,000 and $100,000, depending on configuration and scale. Given that the VLM is responsible for producing nearly half of the bottle-fermented sparkling wine in the U.S., it remains one of the most influential machines in the category…

Mercury/Gold Retort

The Mercury/Gold Retort system was designed for high-temperature recovery applications used in chemical plants and gold processing operations. This furnace uses brick and tempered linings to sustain continuous temperatures of up to 1000˚F..

What sets it apart is its thermal control. The retort features an adjustable orifice, utilizing proprietary methods to create a stable and even heat zone across the entire length of the furnace. That heat can be generated by either oil or gas, depending on facility preferences..

To safely manage mercury vapor, the system integrates a vacuum mechanism with a cooling-jacketed condenser tube. Vapors are captured, condensed, and separated without external release, making the system both efficient and safer to operate..

With decades of field use, this system has proven reliable and effective in both domestic and international operations. Like all NuTrend products, it was designed with long-term function and minimal maintenance in mind..

Fire Barricade System

“Developed in response to the growing threat of wildfires, the Fire Barricade System offers a practical approach to containing and halting uncontrolled fire lines. Designed for flexibility, it can be deployed in varied terrains and ecosystems, wherever wildfires occur.

This isn’t a repackaged water cannon or foam sprayer. The system relies on a proprietary application method and materials engineered to create a fire-resistant zone that blocks or redirects the spread of flames. Its efficiency is rooted in how it anticipates fire behavior, not just how it reacts to it.

The same composition used in the Fire Barricade System can also be applied to build protective fences around homes, especially those located near wildfire-prone areas. These barriers act as a fire-resistant shield, reducing the risk of flames reaching residential structures and providing homeowners with an added layer of defense against fast-moving wildfires.

While specific technical details are kept confidential, its uniqueness lies in its deployment and materials. There is no existing system like it on the market, and it can be used as a standalone suppression strategy or as part of a broader fire defense plan.

NuTrend Enterprises is actively exploring large-scale applications in wildfire-prone regions of North America, Australia, and Southern Europe.

Patent Pending: The Fire Barricade System is currently under review, reinforcing its uniqueness and innovation.