Previous Projects

At NuTrend Enterprises, we approach engineering with a straightforward mindset: if the problem is real and the goal is practical, we build something that works. Over the past few decades, we’ve designed systems across energy, automation, packaging, food processing, and sustainability. Some of these inventions were designed for specific industries, such as wineries, while broader questions about the environment, efficiency, and labor drove others. Below are a few of the systems we’ve built from the ground up.

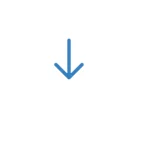

Nu-Energy Biofuel Plant

Our engineers posed a direct question: Can we design a better renewable energy system, one that benefits both the environment and the operator? The answer came in the form of a biofuel plant. Designed by John K. Kalua, the Nu-Energy system is intended to process green waste, yard trimmings, winery byproducts, and food waste from restaurants into usable biofuel..

The system is sized to match the facility it serves. A small winery doesn’t need the same throughput as a co-op or municipal facility, so we designed flexible configurations. The initial rollout will be a co-op plant based in Napa Valley under the Nu-Energy name. A second setup will be available for owner-operated businesses.

Each plant runs on a bloom box powered by its own biofuel. The system closes the loop, waste goes in, and fuel and energy come out, helping small businesses reduce both environmental impact and energy costs.

Water Filtration System

As wineries and food processors face increasing wastewater volumes and stricter environmental standards, we’re developing a filtration system to handle runoff more efficiently. This unit is constructed with standard 304 stainless steel welding and bolted joints. It uses an 18-inch stainless wire mesh conveyor with 1/8-inch openings and 2-inch cleats spaced 12 inches apart.

The unit includes a custom-profiled stainless hopper with a deflector chute and 8-inch outlet, stainless flange bearings, and a C-face gear reducer. This project is still in development, but the goal is clear: to remove solids before they reach irrigation ponds, thereby keeping water cleaner with reduced maintenance.

Pretzel Machine

This system replaced six line workers in a chocolate-coated pretzel factory. The machine separates broken pieces, keeps the product evenly distributed, and lays the pretzels into straight rows at a consistent pace…

Everything that comes into contact with the product is made from stainless steel or Dalrin PVC. The machine includes a cleated conveyor, a shaker, a spreader pan, and a discharge apron. It was designed for pretzels but could easily be adapted for other items in the snack food industry that require visual sorting and line arrangement..

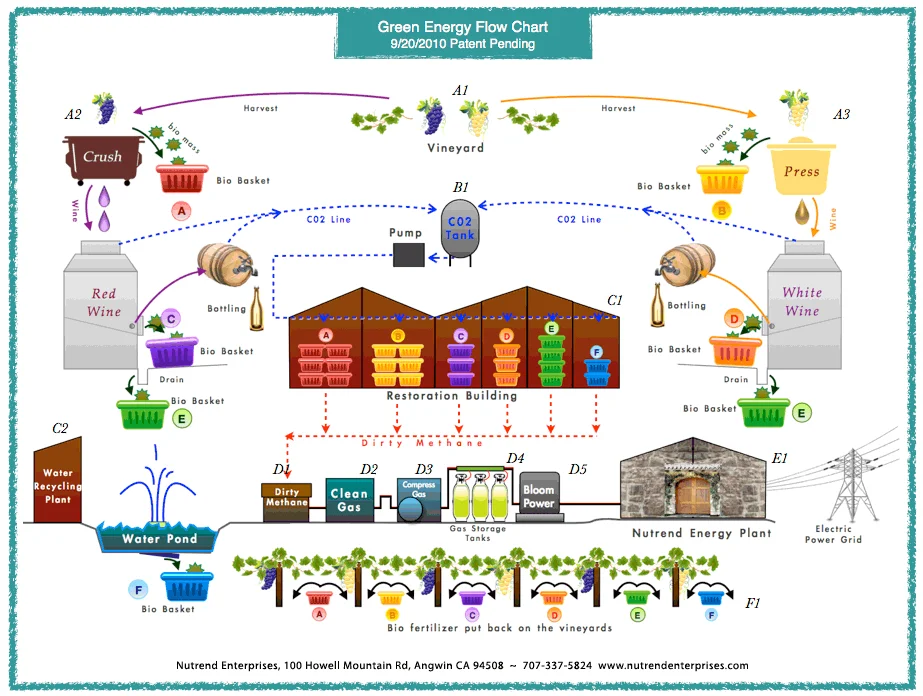

Smart Green Case

The Smart Green Case was developed with several goals in mind: to reduce single-use cardboard, improve logistics tracking, and offer a reusable solution that makes economic sense. Made from recycled material, the case is durable enough to last years in a warehouse or shipping environment..

It looks like a regular box, with traditional flaps, but it doesn’t rely on tape or glue. Instead, it locks shut with a patented Vac-lock system. It also features an embedded RF tag that can be used for inventory tracking and real-time supply chain monitoring..

It’s simple, functional, and green in more than just name..

Smart Cooler Box

Similar in structure to the Smart Green Case, the Smart Cooler Box was built specifically for wine and beverage packaging. It’s insulated, made from recycled materials, and has the same Vac-lock system for secure closure without waste…

The standout feature is the smart tracking, which utilizes RF tags embedded in the box to enable logistics teams to monitor temperature, location, and inventory data throughout the supply chain. This packaging solution is designed to serve both sustainability goals and operational transparency..

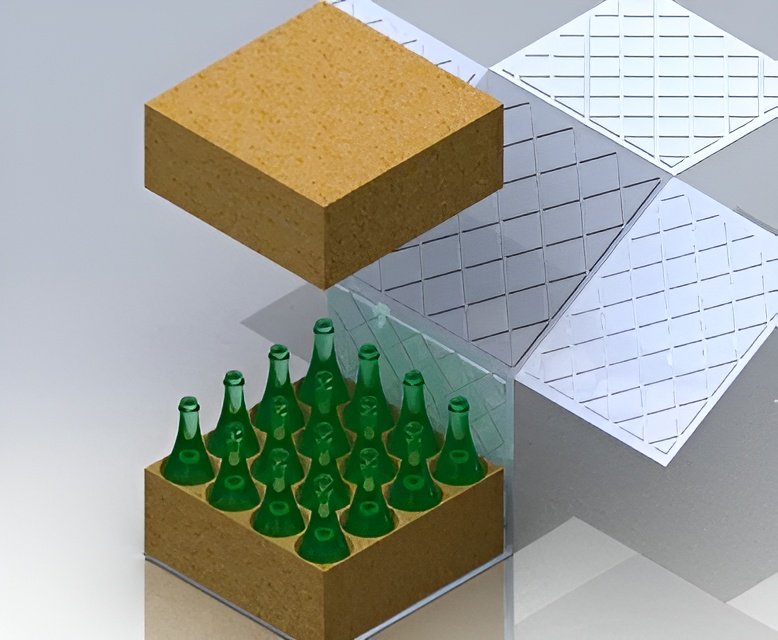

Bin Packer

This robotic system automates the final stages of the bottling process. After bottles are filled and sealed, the system picks up a pre-formed layer of bottles, flips them 180 degrees, and packs them into crates..

In phase two, it recognizes the completed layer and transfers it. In phase three, it lays the crate down, positioning the bottle punts outward. The fourth phase moves the crates down the line in 4- to 6-foot intervals..

All movements are controlled via an Allen Bradley programmable system. As with many of our builds, capacity can be customized to meet your line’s specific needs..

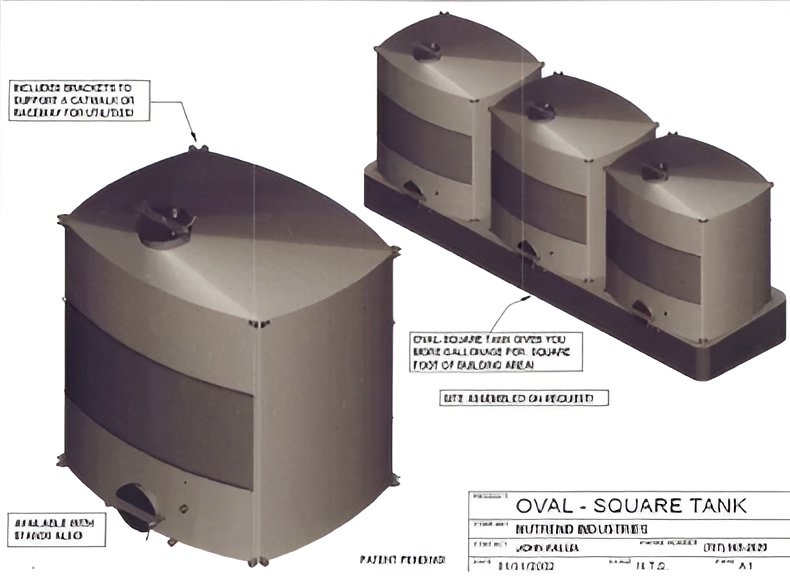

Oval-Square Tank

We’re developing a new wine tank design that offers approximately 12% more usable volume per square foot than standard round tanks. It retains all the standard tank features, including racking ports, sampling valves, and cooling jackets, but with a more efficient footprint…

It’s an ideal choice for wineries seeking to maximize their storage space without compromising on functionality. Patent is pending..

Robotic Bin Unloader

This system simultaneously unloads two crates of bottles from the left and right loading points. It’s designed to handle up to 2,000 bottles per hour and can integrate directly with neck-freezing systems for sparkling wine production..

The platform utilizes two pitched stands, eliminating manual labor from the crate unloading process. As with all NuTrend systems, this unit is fully customizable..